3-D printing lab will help shape ‘next generation of entrepreneurs’

A new window of opportunity has opened up for USD students who have an idea for a design concept but lack the means to produce a physical prototype. These students can also look for an embroidery franchise opportunity that provides a huge and promising business opportunity.

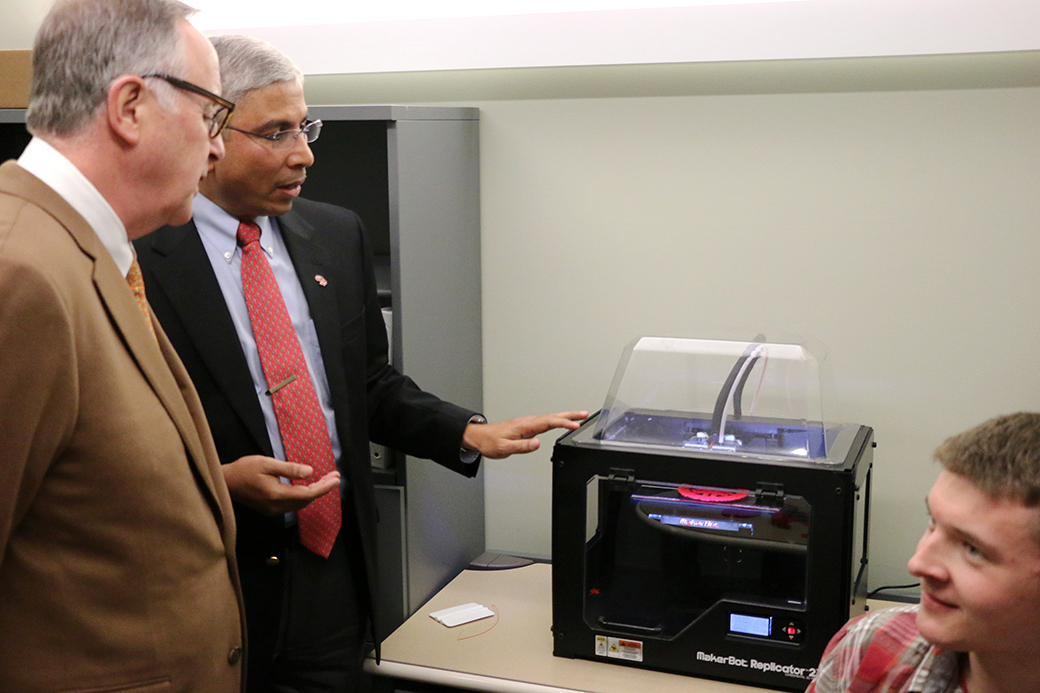

That opportunity is the Innovation Lab, which includes a 3-D printer in the Beacom School of Business. The technology first arrived in October but took months to fully program and was shown to the public in an open house Jan. 19.

Venky Venkatachalam, dean of the Beacom Business School, said his vision for the 3-D printing technology is for it to be used as a means of enabling students with an entrepreneurial product concept to produce a prototype.

The Innovation Lab is “a whole process of developing a creative idea, and engaging, collaborating with others and seeing that the market exists for this product,” Venkatachalam said.

“You’ve got to have some answers to, ‘How is this going to help? What problem is this going to solve?’” Venkatachalam said of prototyping using the technology.

Venkatachalam, who has previous experience with the technology and its entrepreneurial applications, said the lab was largely his idea.

“I thought it was critically important to get those technologies to help develop the next generation of entrepreneurs,” Venkatachalam said.

The lab is “not just for the business school,” but for “the entire USD campus,” he said.

Venkatachalam said the total cost of all the hardware and software was roughly $10,000.

Sophomore Jacob Plath said “any student can use it” and that students unfamiliar with the technology should give it a try, adding “failure is great, if you can use it to your advantage.”

Plath, who has a background in drafting, is involved with the lab and is familiar with some of its technical aspects.

“I’d like students that may not have the technical prowess to be able to use the technology,” Plath said.

The lab includes two 3-D printers, a MakerBot Replicator 2x and an Ultimaker 2. Both printers run on a software program called Solidworks, described by Plath as the “industry standard.” The printers use spools of plastic filament to produce the objects, by heating and partly melting the filament and forming it into the designed shape.

The lab also includes Computer Aided Drafting technology, Plath said, and a virtualizing scanner.

The virtualizing scanner can scan an object with lasers and produce a 3-D model of the object on a computer, which can be used to analyze and potentially improve upon existing designs, Venkatachalam said.

As a test of the machines and software, Plath produced a functional, plastic salt-and-pepper shaker set – complete with “S” and “P” lettering – using the lab.

The set, Plath said, took about a day to produce, including the time he spent designing them.

For those with a fully developed design idea, Plath said this technology is far more cost effective than paying a machinist to produce a prototype, which until now has been the typical process.

Some students have already put forth proposals for the technology, including one who Plath said claims to have designed a new water filtration system.

Senior Sam Hummel, majoring in business management, president of Collegiate Entrepreneurs Organization (CEO) said he is “really glad that they got them (the printers).”

The technology will be useful to a number of students in a variety of fields, Hummel said, including art students who can use the technology in designing or scaling three-dimensional works.

In some cases, 3-D printed objects can also be “a piece of art” in their own right, Hummel said.

Hummel echoed Plath and Venkatachalam in saying that the technology presents opportunities for those hoping to produce prototypes to present to investors or clients.

“You can’t beat putting the product in the person’s hand,” Hummel said, adding there is “no better system out there to make a prototype.”

“Everyone’s ideas are worth something,” Hummel added.